3.3.1 SP162 Amend to read as follows: „(Deleted)”.

SP181 Insert „(see 5.2.2.2.2)” after „model No.1”.

SP204 Amend to read as follows: „(Deleted)”.

SP216 In the last sentence, insert „and articles” before „containing” and amend the end to read: „...free liquid in the packet or article.”.

SP247 Amend the end of the first paragraph to read:

„...may be carried in wooden barrels with a capacity of more than 250 litres and not more than 500 litres meeting the general requirements of 4.1.1, as appropriate, on the following conditions:...”.

Replace the word „casks” with „wooden barrels” (5 times).

SP251 In the first sentence, add „for example” before „for medical,” add „or repair” before „purposes”.

SP282 Amend to read as follows: „(Deleted)”.

SP289 Replace „vehicles” and „vehicle” with „conveyances” and „conveyance”, respectively.

SP292 Amend to read as follows:

„Mixtures containing not more than 23.5% oxygen by volume may be carried under this entry when no other oxidizing gases are present. A label conforming to model 5.1 is not required for any concentrations within this limit.”.

SP298 Amend to read as follows: „(Deleted)”.

SP303 Amend to read as follows:

„Receptacles shall be assigned to the classification code of the gas or mixture of gases contained therein determined in accordance with the provisions of section 2.2.2.”.

SP309 Amend to read as follows:

„This entry applies to non sensitized emulsions, suspensions and gels consisting primarily of a mixture of ammonium nitrate and fuel, intended to produce a Type E blasting explosive only after further processing prior to use.

The mixture for emulsions typically has the following composition: 60-85% ammonium nitrate, 5-30% water, 2-8% fuel, 0.5-4% emulsifier agent, 0-10% soluble flame suppressants, and trace additives. Other inorganic nitrate salts may replace part of the ammonium nitrate.

The mixture for suspensions and gels typically has the following composition: 60-85% ammonium nitrate, 0-5% sodium or potassium perchlorate, 0-17% hexamine nitrate or monomethylamine nitrate, 5-30% water, 2-15% fuel, 0.5-4% thickening agent, 0-10% soluble flame suppressants, and trace additives. Other inorganic nitrate salts may replace part of the ammonium nitrate.

Substances shall satisfactorily pass Test Series 8 of the Manual of Tests and Criteria, Part I, Section 18 and be approved by the competent authority.”.

SP316 Delete „or hydrated”.

SP319 Delete the first sentence.

SP320 Amend to read as follows: „(Deleted)”.

SP601 Amend to read as follows:

„Pharmaceutical products (medicines) ready for use, which are substances manufactured and packaged for retail sale or distribution for personal or household consumption are not subject to the requirements of ADR.”

SP617 Delete „and shall be specified in the transport document”.

SP634 Amend to read as follows: „(Deleted)”.

SP645 Add the following new sentence at the end:

„When assignment to a division is made in accordance with the procedure in 2.2.1.1.7.2, the competent authority may require the default classification to be verified on the basis of test data derived from Test Series 6 of the Manual of Tests and Criteria, Part I, Section 16.”.

SP 651 Amend to read as follows:

„Special Provision V2 (1) does not apply if the net explosive mass per transport unit does not exceed 4000 kg, provided that the net explosive mass per vehicle does not exceed 3000 kg.”.

Add the following new special provisions:

„322 When carried in non-friable tablet form, these goods are assigned to packing group III.

323 (Reserved)

324 This substance needs to be stabilized when in concentrations of not more than 99%.

325 In the case of non-fissile or fissile excepted uranium hexafluoride, the material shall be classified under UN No 2978.

326 In the case of fissile uranium hexafluoride, the material shall be classified under UN No. 2977.

327 Waste aerosols consigned in accordance with 5.4.1.1.3 may be carried under this entry for the purposes of reprocessing or disposal. They need not be protected against inadvertent discharge provided that measures to prevent dangerous build up of pressure and dangerous atmospheres are addressed. Waste aerosols, other than those leaking or severely deformed, shall be packed in accordance with packing instruction P003 and special provision PP87, or packing instruction LP02 and special packing provision L2. Leaking or severely deformed aerosols shall be carried in salvage packagings provided appropriate measures are taken to ensure there is no dangerous build up of pressure.

NOTE: For maritime carriage, waste aerosols shall not be carried in closed containers.

328 This entry applies to fuel cell cartridges containing flammable liquids including methanol or methanol/water solutions. Fuel cell cartridge means a container that stores fuel for discharge into fuel cell powered equipment through a valve(s) that controls the discharge of fuel into such equipment and is free of electric charge generating components. The cartridge shall be designed and constructed to prevent the fuel from leaking during normal conditions of carriage.

This entry applies to fuel cell cartridge design types shown without their packaging to pass an internal pressure test at a pressure of 100 kPa (gauge).

329 (Reserved)

330 Alcohols containing petroleum products (e.g. gasoline) up to 5% shall be carried under the entry UN 1987 ALCOHOLS, N.O.S.

652 Austenitic stainless steel, ferritic and austenitic steel (Duplex steel) and welded titanium receptacles which do not meet the requirements of Chapter 6.2 but have been constructed and approved in accordance with national aviation provisions for use as hot air balloon or hot air ship fuel receptacles, brought into service (date of initial inspection) before 1 July 2004, may be carried by road provided they meet the following conditions:

(a) The general provisions of 6.2.1 shall be complied with;

(b) The design and construction of the receptacles shall have been approved for aviation use by a national air transport authority;

(c) As an exemption from 6.2.1.1.1, the calculation pressure shall be derived from a reduced maximum ambient temperature of +40° C; in this case:

(i) as an exemption from 6.2.1.2, cylinders may be manufactured from rolled and annealed commercially pure titanium with the minimum requirements of Rm>450 MPa, εA>20% εA = elongation after fracture);

(ii) austenitic stainless steel and ferritic and austenitic steel (Duplex steel) cylinders may be used with a stress level up to 85% of the minimum guaranteed yield strength (Re) at a calculation pressure derived from a reduced maximum ambient temperature of +40° C;

(iii) the receptacles shall be equipped with a pressure relief device having a nominal set pressure of 26 bar; the test pressure of these receptacles shall be not less than 30 bar;

(d) When the exemptions from (c) are not applied, the receptacles shall be designed for a reference temperature of 65° C and shall be equipped with relief devices with a nominal set pressure specified by the competent authority of the country of use;

(e) The main body of the receptacles shall be covered by an outer, water-resistant protective layer at least 25 mm thick made from structural cellular foam or similar material;

(f) During carriage, the cylinder shall be firmly secured in a crate or an additional safety device;

(g) The receptacles shall be marked with a clear, visible label stating that the receptacles are for use only in hot air balloons and hot air ships;

(k) The duration of service (from the date of initial inspection) shall not exceed 25 years.”

653 The carriage of this gas in cylinders with a maximum capacity of 0.5 litres, is not subject to the other provisions of ADR if the following conditions are met:

- The provisions for construction and testing of cylinders are observed;

- The cylinders are contained in outer packagings which at least meet the requirements of Part 4 for combination packagings. The general provisions of packing of 4.1.1.1, 4.1.1.2 and 4.1.1.5 to 4.1.1.7 shall be observed;

- The cylinders are not packed together with other dangerous goods;

- The total gross mass of a package does not exceed 30 kg; and

- Each package is clearly and durably marked with „UN 1013”. This marking is displayed within a diamond-shaped area surrounded by a line that measures at least 100 mm by 100 mm.”

3.4.6 In the first column of table 3.4.6 replace „LQ4” and „LQ5” with „LQ4c” and „LQ5c” respectively.

In the table, for LQ19, replace respectively „3 l” and „1 l” with „5 kg”.

Renumber all references to renumbered paragraphs of Chapters 6.1, 6.5 and 6.6, as appropriate.

4.1.1.2 In the Note, delete „high and medium molecular mass”.

4.1.1.5 Insert the following new second sentence:

„Inner packagings containing liquids shall be packed with their closures upward and placed within outer packagings consistent with the orientation markings prescribed in 5.2.1.9.”.

4.1.1.5.1 Insert a new paragraph 4.1.1.5.1 with the same text as in existing 6.1.5.1.6 with the insertion of the words „or a large packaging” after „combination packaging” and the words „or large packaging” after „outer packaging” in the first sentence.

4.1.1.8 Amend to read as follows:

„4.1.1.8 Where pressure may develop in a package by the emission of gas from the contents (as a result of temperature increase or other causes), the packaging or IBC may be fitted with a vent provided that the gas emitted will not cause danger on account of its toxicity, its flammability or the quantity released, for example.

A venting device shall be fitted if dangerous overpressure may develop due to normal decomposition of substances. The vent shall be so designed that, when the packaging or IBC is in the attitude in which it is intended to be carried, leakages of liquid and the penetration of foreign substances are prevented under normal conditions of carriage.

NOTE: Venting of the package is not permitted for air carriage.

4.1.1.8.1 Liquids may only be filled into inner packagings which have an appropriate resistance to internal pressure that may be developed under normal conditions of carriage.”.

4.1.1.12 In the first sentence, replace ”, including IBCs,” with „as specified in Chapter 6.1” and delete ”, or 6.5.4.7 for the various types of IBCs”.

Delete (c).

In the last paragraph, delete ”, or IBC,” in the first sentence and „or IBC” in the second sentence.

4.1.1.18.3 Add a new paragraph to read as follows:

„4.1.1.18.3 Appropriate measures shall be taken to ensure that there is no dangerous build up of pressure.”.

Consequential amendment: In 4.1.1.18.1, add at the end „and 4.1.1.18.3”.

4.1.1.19.1 In the first sentence, delete „high and medium molecular mass” and „high molecular mass”.

4.1.1.19.6 In the table:

In Note * to UN No 1791: Replace „For hypochlorite solutions” with „If the test is carried out with hypochlorite solutions themselves”.

For UN No 3264, fourth entry, Column „Standard liquid”, insert a semicolon after „Rules for collective entries”.

4.1.2.2 Replace the first sentence with the following paragraph:

„Every metal, rigid plastics and composite IBC, shall be inspected and tested, as relevant, in accordance with 6.5.4.4 or 6.5.4.5:

(a) before it is put into service;

(b) thereafter at intervals not exceeding two and a half and five years, as appropriate;

(c) after the repair or remanufacture, before it is re-used for carriage.”

Amend the end of the second sentence (starting with „An IBC shall not be filled...”) to read as follows: „... expiry of the last periodic test or inspection.”.

4.1.3.6 Amend to read as follows:

„4.1.3.6 Pressure receptacles for liquids and solids

4.1.3.6.1 Unless otherwise indicated in ADR, pressure receptacles conforming to:

(a) the applicable requirements of Chapter 6.2; or

(b) the national or international standards on the design, construction, testing, manufacturing and inspection, as applied by the country in which the pressure receptacles are manufactured, provided that the provisions of 4.1.3.6 are met, and that, for metallic cylinders, tubes, pressure drums and bundles of cylinders, the construction is such that the minimum burst ratio (burst pressure divided by test pressure) is:

(i) 1.50 for refillable pressure receptacles;

(ii) 2.00 for non-refillable pressure receptacles,

are authorized for the carriage of any liquid or solid substance other than explosives, thermally unstable substances, organic peroxides, self-reactive substances, substances where significant pressure may develop by evolution of chemical reaction and radioactive material (unless permitted in 4.1.9).

This sub-section is not applicable to the substances mentioned in 4.1.4.1, packing instruction P200, table 3 and in 4.1.4.4.

4.1.3.6.2 Every design type of pressure receptacle shall be approved by the competent authority of the country of manufacture or as indicated in Chapter 6.2.

4.1.3.6.3 Unless otherwise indicated, pressure receptacles having a minimum test pressure of 0.6 MPa shall be used.

4.1.3.6.4 Unless otherwise indicated, pressure receptacles may be provided with an emergency pressure relief device designed to avoid bursting in case of overfill or fire accidents.

Pressure receptacle valves shall be designed and constructed in such a way that they are inherently able to withstand damage without release of the contents or shall be protected from damage which could cause inadvertent release of the contents of the pressure receptacle, by one of the methods as given in 4.1.6.8 (a) to (f).

4.1.3.6.5 The level of filling shall not exceed 95% of the capacity of the pressure receptacle at 50 °C. Sufficient ullage (outage) shall be left to ensure that the pressure receptacle will not be liquid full at a temperature of 55 °C.

4.1.3.6.6 Unless otherwise indicated pressure receptacles shall be subjected to a periodic inspection and test every 5 years. The periodic inspection shall include an external examination, an internal examination or alternative method as approved by the competent authority, a pressure test or equivalent effective non-destructive testing with the agreement of the competent authority including an inspection of all accessories (e.g. tightness of valves, emergency relief valves or fusible elements). Pressure receptacles shall not be filled after they become due for periodic inspection and test but may be carried after the expiry of the time limit. Pressure receptacle repairs shall meet the requirements of 4.1.6.11.

4.1.3.6.7 Prior to filling, the packer shall perform an inspection of the pressure receptacle and ensure that the pressure receptacle is authorized for the substances to be carried and that the requirements of ADR have been met. Shut-off valves shall be closed after filling and remain closed during carriage. The consignor shall verify that the closures and equipment are not leaking.

4.1.3.6.8 Refillable pressure receptacles shall not be filled with a substance different from that previously contained unless the necessary operations for change of service have been performed.

4.1.3.6.9 Marking of pressure receptacles for liquids and solids according to 4.1.3.6 (not conforming to the requirements of Chapter 6.2) shall be in accordance with the requirements of the competent authority of the country of manufacturing.”.

4.1.4.1 P001 Insert a new row after „Composite packagings” to read as follows:

„Pressure receptacles may be used provided that the general provisions of 4.1.3.6 are met.”.

Amend special packing provision PP2, to read as follows:

„PP2 For UN 3065, wooden barrels with a maximum capacity of 250 litres and which do not meet the provisions of Chapter 6.1 may be used.”.

P002 Insert a new row after „Composite packagings” to read as follows:

„Pressure receptacles may be used provided that the general provisions of 4.1.3.6 are met.”.

In special packing provision PP37, amend the second sentence to read as follows:

„All bags of any type shall be carried in closed vehicles or containers or be placed in closed rigid overpacks.”.

P003 Add the following new special packing provisions PP17, PP87 and PP88:

„PP17 For UN Nos. 1950 and 2037, packages shall not exceed 55 kg net mass for fibreboard packagings or 125 kg net mass for other packagings.

PP87 For UN 1950 waste aerosols carried in accordance with special provision 327, the packagings shall have a means of retaining any free liquid that might escape during carriage, e.g. absorbent material. The packaging shall be adequately ventilated to prevent the creation of flammable atmosphere and the build-up of pressure.

PP88 For UN 3473 when fuel cell cartridges are packed with equipment, they shall be packed in inner packagings or placed in the outer packaging with cushioning material so that the cartridges are protected against damage that may be caused by the movement or placement of the equipment and the cartridges within the outer packaging.”.

Add a new row at the end to read as follows:

„Special packing provision specific to RID and ADR:

RR6 For UN 1950 and 2037 in the case of carriage by full load, metal articles may also be packed as follows: the articles shall be grouped together in units on trays and held in position with an appropriate plastics cover; these units shall be stacked and suitably secured on pallets.”.

P200 In paragraph (5)(b), in the sentence preceding the first equation, replace „gases for which data are not provided in the table” with „gases and gas mixtures for which relevant data are not available”.

In paragraph (5)(c), in the sentence before the equation, replace „gases for which filling data are not provided in the table” with „gases and gas mixtures for which relevant data are not available”.

In paragraph (10), amend special provisions „k”, „l”, „n” and „z” as follows:

Special provision „k”: Add the following text before the third paragraph:

„Bundles containing UN 1045 Fluorine, compressed, may be constructed with isolation valves on assemblies (groups) of cylinders not exceeding 150 litres total water capacity instead of isolation valves on every cylinder.

Cylinders and individual cylinders within a bundle shall have a test pressure greater than or equal to 200 bar and a minimum wall thickness of 3.5 mm for aluminium alloy or 2 mm for steel. Individual cylinders not complying with this requirement shall be carried in a rigid outer packaging that will adequately protect the cylinder and its fittings and meeting the packing group I performance level. Pressure drums shall have a minimum wall thickness as specified by the competent authority.”

Special provision „l”: In the last sentence, replace „total quantity” with „maximum net mass”.

Special provision „n”: Amend to read as follows:

For UN 2190, oxygen difluoride, compressed, cylinders and individual cylinders within a bundle shall contain not more than 5kg of the gas;

For UN 1045 fluorine, compressed, cylinders, individual cylinders within a bundle and assemblies of cylinders within a bundle shall contain not more than 5 kg of the gas. Bundles containing this gas may be divided in assemblies (groups) of cylinders not exceeding 150 litres total water capacity.

Special provision „z”: Amend the third paragraph to read as follows:

„Toxic substances with an LC50 less than or equal to 200 ml/m3 shall not be carried in tubes, pressure drums or MEGCs and shall meet the requirements of special packing provision „k”. However, UN 1975 Nitric oxide and dinitrogen tetroxide mixture may be carried in pressure drums.”.

In Tables 1 and 2, delete the entries for the following UN Nos.: 1014, 1015, 1979, 1980, 1981 and 2600.

In Table 1, in the heading of column 11, replace „Working pressure, bar” with „Maximum working pressure, bar”

In Table 2:

- For UN Nos. 2192 and 2199, add „q” (twice for UN No. 2199) in the column under the heading „Special packing provisions”.

- For UN 2451, delete „300” and „0.75” in the columns for „Test pressure” and „Filling ratio”, respectively.

In paragraph (10) ta (b), delete „or standard EN 1439:1996 ’Transportable refillable steel cylinders for liquefied petroleum Gases (LPG) - Procedures for checking before, during and after refilling’”.

In paragraph (11), in the table, add „+A1:2005” after „EN 13365:2002”, and insert the following new rows:

| Applicable requirements | Reference | Title of document | |

| (7) and (10) ta (b) | EN 1439:2005 (except 3.5 and Annex C) | LPG equipment and accessories - Transportable refillable welded and brazed steel Liquefied Petroleum Gas (LPG) cylinders - Procedures for checking before, during and after filling | |

| (7) and (10) ta (b) | EN 14794:2005 | LPG equipment and accessories - Transportable refillable aluminium cylinders for liquefied petroleum gas (LPG) - Procedure for checking before, during and after filling |

P204 Amend to read as follows: „(Deleted)”.

P400 (1) Amend to read as follows:

„Pressure receptacles may be used provided that the general provisions of 4.1.3.6 are met. They shall be made of steel and shall be subjected to an initial test and periodic tests every 10 years at a pressure of not less than 1 MPa (10 bar, gauge pressure). During carriage, the liquid shall be under a layer of inert gas with a gauge pressure of not less than 20 kPa (0.2 bar).”.

P401 (1) and P402 (1) Amend to read as follows:

„Pressure receptacles may be used provided that the general provisions of 4.1.3.6 are met. They shall be made of steel and subjected to an initial test and periodic tests every 10 years at a pressure of not less than 0.6 MPa (6 bar, gauge pressure). During carriage, the liquid shall be under a layer of inert gas with a gauge pressure of not less than 20 kPa (0.2 bar).”.

P403, P404 and P410 Insert a new row after „Composite packagings” to read as follows:

„Pressure receptacles may be used provided that the general provisions of 4.1.3.6 are met.”.

P520 Under „Additional requirements” in „4.”, insert „(model No.1, see 5.2.2.2.2)” after „risk label”.

P601 and P602 Amend paragraph (1) to read as follows:

„(1) Combination packagings with a maximum gross mass of 15 kg, consisting of

- one or more glass inner packaging(s) with a maximum capacity of 1 litre each and filled to not more than 90% of their capacity; the closure(s) of which shall be physically held in place by any means capable of preventing back-off or loosening by impact or vibration during carriage, individually placed in

- metal receptacles together with cushioning and absorbent material sufficient to absorb the entire contents of the glass inner packaging(s), further packed in

- 1A2, 1B2, 1N2, 1H2, 1D, 1G, 4A, 4B, 4C1, 4C2, 4D, 4F, 4G or 4H2 outer packagings.”.

Amend paragraph (4) to read as follows:

„(4) Pressure receptacles may be used provided that the general provisions of 4.1.3.6 are met. They shall be subjected to an initial test and periodic tests every 10 years at a pressure of not less than 1 MPa (10 bar) (gauge pressure). Pressure receptacles may not be equipped with any pressure relief device. Each pressure receptacle containing a toxic by inhalation liquid with an LC50 less than or equal to 200 ml/m3 (ppm) shall be closed with a plug or valve conforming to the following:

(a) Each plug or valve shall have a taper-threaded connection directly to the pressure receptacle and be capable of withstanding the test pressure of the pressure receptacle without damage or leakage;

(b) Each valve shall be of the packless type with non-perforated diaphragm, except that, for corrosive substances, a valve may be of the packed type with an assembly made gas-tight by means of a seal cap with gasket joint attached to the valve body or the pressure receptacle to prevent loss of substance through or past the packing;

(c) Each valve outlet shall be sealed by a threaded cap or threaded solid plug and inert gasket material;

(d) The materials of construction for the pressure receptacle, valves, plugs, outlet caps, luting and gaskets shall be compatible with each other and with the contents.

Each pressure receptacle with a wall thickness at any point of less than 2.0 mm and each pressure receptacle which does not have fitted valve protection shall be carried in an outer packaging. Pressure receptacles shall not be manifolded or interconnected.”.

P650 Amend paragraph (2) to read as follows:

„(2) The packaging shall consist of at least three components:

(a) A primary receptacle;

(b) A secondary packaging; and

(c) An outer packaging

of which either the secondary or the outer packaging shall be rigid.”

In paragraph (4):

Amend the second sentence to read as follows: „The mark shall be in the form of a square set at an angle of 45° (diamond-shaped) with minimum dimensions of 50 mm by 50 mm; the width of the line shall be at least 2 mm and the letters and numbers shall be at least 6 mm high.”.

Add the following new third sentence: „The proper shipping name „BIOLOGICAL SUBSTANCE, CATEGORY B” in letters at least 6 mm high shall be marked on the outer packaging adjacent to the diamond-shaped mark.”.

Insert a new paragraph (5) to read as follows and renumber subsequent paragraphs accordingly:

„(5) At least one surface of the outer packaging shall have a minimum dimension of 100 mm x 100 mm.”.

Amend current paragraph (5) (renumbered (6)) to read as follows:

„(6) The completed package shall be capable of successfully passing the drop test in 6.3.2.5 as specified in 6.3.2.2 to 6.3.2.4 at a height of 1.2 m. Following the appropriate drop sequence, there shall be no leakage from the primary receptacle(s) which shall remain protected by absorbent material, when required, in the secondary packaging.”.

In (7) (renumbered (8)), add a new sub-paragraph (d) to read as follows:

„(d) If there is any doubt as to whether or not residual liquid may be present in the primary receptacle during carriage then a packaging suitable for liquids, including absorbent materials, shall be used.”.

Insert a new paragraph (10) to read as follows:

„(10) When packages are placed in an overpack, the package markings required by this packing instruction shall either be clearly visible or be reproduced on the outside of the overpack.”.

Current paragraphs (9) and (10) become (11) and (12).

Add a new paragraph (13) to read as follows:

„(13) Other dangerous goods shall not be packed in the same packaging as Class 6.2 infectious substances unless they are necessary for maintaining the viability, stabilizing or preventing degradation or neutralizing the hazards of the infectious substances. A quantity of 30 ml or less of dangerous goods included in Classes 3, 8 or 9 may be packed in each primary receptacle containing infectious substances. When these small quantities of dangerous goods are packed with infectious substances in accordance with this packing instruction no other requirements of ADR need be met.”.

Current paragraph (11) becomes (14).

P800 Amend paragraph (1) to read as follows:

„(1) Pressure receptacles may be used provided that the general provisions of 4.1.3.6 are met.”.

In paragraph (2), replace „2.5 l” with „3 l”.

P802 In paragraph (4), delete „Austenitic”.

Amend paragraph (5) to read as follows:

„(5) Pressure receptacles may be used provided that the general provisions of 4.1.3.6 are met.”.

4.1.4.2 IBC02 Add a new row at the end to read as follows:

„Special packing provision specific to RID and ADR:

BB2 For UN No.1203, notwithstanding special provision 534 (see 3.3.1), IBCs shall only be used when the actual vapour pressure is not more than 110 kPa at 50 °C, or 130 kPa at 55 °C.”.

4.1.4.3 LP02 Add a new special packing provision „L2” to read as follows:

„L2 For UN 1950 aerosols, the large packaging shall meet the Packing Group III performance level. Large packagings for waste aerosols carried in accordance with special provision 327 shall have in addition a means of retaining any free liquid that might escape during carriage e.g. absorbent material.”.

4.1.6.2 (b) Replace „mass” with „material”.

4.1.9.1.3 Amend to read:

„A package shall not contain any items other than those that are necessary for the use of the radioactive material. The interaction between these items and the package under the conditions of carriage applicable to the design, shall not reduce the safety of the package.”.

4.1.9.2.2 Amend to read: „For LSA material and SCO which is or contains fissile material the applicable requirements of 6.4.11.1 and 7.5.11 CV33 (4.1) and (4.2) shall be met.”.

4.1.10.4 MP 20 Amend the second sentence to read as follows:

„Shall not be packed together with goods and articles of Class 1 having different UN numbers, except if provided for by special provision MP 24.”

MP 22 Amend the second sentence to read as follows:

„Shall not be packed together with goods of Class 1 having different UN numbers, except

(a) With their own means of initiation, provided that the means of initiation will not function under normal conditions of carriage; or

(b) With articles of compatibility groups C, D and E; or

(c) If provided for by special provision MP 24.”

MP 23 Amend the second sentence to read as follows:

„Shall not be packed together with goods and articles of Class 1 having different UN numbers, except

(a) With their own means of initiation, provided that the means of initiation will not function under normal conditions of carriage; or

(b) If provided for by special provision MP 24.”.

4.2.1.15 Add a new sub-section to read as follows:

„4.2.1.15 Additional provisions applicable to the carriage of Class 6.2 substances in portable tanks

(Reserved).”.

Renumber subsequent paragraphs accordingly.

Consequential amendments: In 4.2.5.3 TP4 replace „4.2.1.15.2” with „4.2.1.16.2”. In 4.2.5.3 TP33 replace „4.2.1.18” with „4.2.1.19”.

4.2.5.1.1 Add a note at the end of the paragraph to read as follows:

„NOTE: The gases authorized for carriage in MEGCs are indicated with the letter „(M)” in Column (10) of Table A of Chapter 3.2.”.

4.3.2.1.7 Add a new paragraph to read as follows:

„4.3.2.1.7 The tank record shall be retained by the owner or the operator who shall be able to provide this documentation at the request of the competent authority. The tank record shall be maintained throughout the life of the tank and retained for 15 months after the tank is taken out of service.

Should a change of owner or operator occur during the life of the tank the tank record shall be transferred to the new owner or operator.

Copies of the tank record or all necessary documents shall be made available to the expert for tests, inspections and checks on tanks in accordance with 6.8.2.4.5 or 6.8.3.4.16, on the occasion of periodic inspections or exceptional checks.”

4.3.4.1.2 In the table, for tank code L1,5BN, amend the first three entries to read as follows:

| L1.5BN | 3 | F1 | II vapour pressure at 50 °C > 1.1 bar | |

| F1 | III flash-point < 23 °C, viscous, vapour pressure at 50 °C > 1.1 bar boiling point > 35 °C | |||

| D | II vapour pressure at 50 °C > 1.1 bar |

- In the table, include the following amendments under tank code L4BN in column (4):

- first entry (Class 3, classification code F1), read: „I, III, boiling point > 35 °C”

- third entry (Class 3, classification code D), delete: „vapour pressure at 50 °C > 1.75 bar”.

In „Hierarchy of tanks”, first paragraph, replace „the first part of the code (L or S) remains unchanged and that any other” with „any” and replace „parts 2 to 4” with „parts 1 to 4”. Before „Part 2: Calculation pressure”, insert

„Part 1: Types of tanks

S → L”.

Amend the paragraph before the note to read as follows:

„For example:

- A tank with the tank code L10CN is authorized for the carriage of a substance to which the tank code L4BN has been assigned;

- A tank with the tank code L4BN is authorized for the carriage of a substance to which the tank code SGAN has been assigned.”.

5.1.2.1 (a) Re-arrange the text to read as follows:

„An overpack shall be:

(i) marked with the word „OVERPACK”; and

(ii) marked with the UN number preceded by the letters „UN”, and labelled as required for packages in 5.2.2, for each item of dangerous goods contained in the overpack,

unless the markings and the labels representative of all dangerous goods contained in the overpack are visible. If the same marking or the same label is required for different packages, it only needs to be applied once.”.

Insert the following new sentence at the end:

„The marking of the word „OVERPACK”, which shall be readily visible and legible, shall be in an official language of the country of origin and also, if that language is not English, French or German, in English, French or German, unless agreements, if any, concluded between the countries concerned in the transport operation provide otherwise.”

5.1.2.2 Delete the second sentence („The „overpack” marking is an indication of compliance with this requirement.”).

5.1.2.3 Add a new sub-section to read as follows:

„5.1.2.3 Each package bearing package orientation markings as prescribed in 5.2.1.9 and which is overpacked or placed in a large packaging shall be oriented in accordance with such markings.”.

Consequential amendment: Renumber existing 5.1.2.3 as 5.1.2.4.

5.1.5.1.2 (c) Amend to read:

„For each package requiring competent authority approval, it shall be ensured that all the requirements specified in the approval certificates have been satisfied;”.

5.1.5.2.2 (c) Amend to read:

„The shipment of packages containing fissile materials if the sum of the criticality safety indexes of the packages in a single vehicle or container exceeds 50; and”.

5.1.5.2.4 (d) In (v), insert „symbol” after „SI prefix”.

5.2.1.4 Add „and large packagings” after „capacity”.

5.2.1.7.4 (c) Amend the end of the sentence to read as follows: „...origin of design and either the name of the manufacturer or other identification of the packaging specified by the competent authority of the country of origin of design.”.

5.2.1.7.8 Add the following new paragraph:

„5.2.1.7.8 In case of international carriage of packages requiring competent authority design or shipment approval, for which different approval types apply in the different countries concerned, marking shall be in accordance with the certificate of the country of origin of the design.”.

5.2.1.8 Add a new 5.2.1.8 to read as follows:

„5.2.1.8 (Reserved)”.

5.2.1.9 Add a new sub-section to read as follows:

„5.2.1.9 Orientation arrows

5.2.1.9.1 Except as provided in 5.2.1.9.2:

- combination packagings having inner packagings containing liquids;

- single packagings fitted with vents; and

- cryogenic receptacles intended for the carriage of refrigerated liquefied gases,

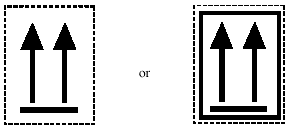

shall be legibly marked with package orientation arrows which are similar to the illustration shown below or with those meeting the specifications of ISO 780:1985. The orientation arrows shall appear on two opposite vertical sides of the package with the arrows pointing in the correct upright direction. They shall be rectangular and of a size that is clearly visible commensurate with the size of the package. Depicting a rectangular border around the arrows is optional.

Two black or red arrows on white or suitable contrasting background. The rectangular border is optional.

5.2.1.9.2 Orientation arrows are not required on packages containing:

(a) pressure receptacles except for closed cryogenic receptacles;

(b) dangerous goods in inner packagings of not more than 120 ml which are prepared with sufficient absorbent material between the inner and outer packagings to completely absorb the liquid contents;

(c) Class 6.2 infectious substances in primary receptacles of not more than 50 ml;

(d) Class 7 radioactive material in Type IP-2, IP-3, A, B(U), B(M) or C packages; or

(e) articles which are leak-tight in all orientations (e.g. alcohol or mercury in thermometers, aerosols, etc.).

5.2.1.9.3 Arrows for purposes other than indicating proper package orientation shall not be displayed on a package marked in accordance with this sub-section.”.

5.2.2.1.7 Add „and large packagings” after „capacity”.

5.2.2.1.11.2 (b) Insert „symbol” after „SI prefix”.

5.2.2.1.11.5 Add the following new paragraph:

„5.2.2.1.11.5 In case of international carriage of packages requiring competent authority design or shipment approval, for which different approval types apply in the different countries concerned, labelling shall be in accordance with the certificate of the country of origin of design.”.

5.2.2.1.12 Delete.

Consequential amendments:

3.2.1 In the explanatory note for column (5), delete the second indent.

5.1.2.1 (b) Amend to read as follows:

„Orientation arrows illustrated in 5.2.1.9 shall be displayed on two opposite sides of the following overpacks:

(i) overpacks containing packages which shall be marked in accordance with 5.2.1.9.1, unless the marking remains visible, and

(ii) overpacks containing liquids in packages which need not be marked in accordance with 5.2.1.9.2, unless the closures remain visible.”

5.2.2.2.1.1 In the first sentence, delete ”, except label conforming to model No. 11,”. Delete the third sentence („Label conforming to model No. 11 ...”).

5.2.2.2.1.3 In the first sentence, delete ”, except label conforming to model No. 11,”.

5.2.2.2.2 Delete label No. 11 and the text under this label.

5.2.2.2.1 Add the following note at the end of the existing text:

„NOTE: Where appropriate, labels in 5.2.2.2.2 are shown with a dotted outer boundary as provided for in 5.2.2.2.1.1. This is not required when the label is applied on a background of contrasting colour.”.

5.2.2.2.1.1 Add the following sentence after the second sentence: „Labels shall be displayed on a background of contrasting colour, or shall have either a dotted or solid outer boundary line.”.

5.2.2.2.1.2 Insert the following new paragraph at the end.

„Empty uncleaned pressure receptacles for gases of Class 2 may be carried with obsolete or damaged labels for the purposes of refilling or inspection as appropriate and the application of a new label in conformity with current regulations or for the disposal of the pressure receptacle.”.

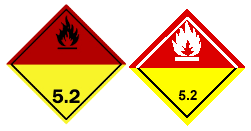

5.2.2.2.2 In the labels for Classes 5.1 and 5.2:

Replace the text under label No. 5.1 with the following:

„(No. 5.1)

Symbol (flame over circle): black; Background: yellow

Figure „5.1” in bottom corner”

Replace label No. 5.2 and the text under the label with the following:

„(No. 5.2)

Symbol (flame): black or white;

Background: upper half red; lower half yellow;

Figure „5.2” in bottom corner”.

5.3.1.1.1 Add the following sentence at the end: „Placards shall be displayed on a background of contrasting colour, or shall have either a dotted or solid outer boundary line.”.

5.3.1.1.2 Add the following subparagraph at the end:

„Placards are not required for the carriage of explosives of Division 1.4, compatibility group S.”

5.3.1.5.1 Amend to read as follows:

„5.3.1.5.1 For vehicles carrying packages containing substances or articles of Class 1 (other than of Division 1.4, compatibility group S), placards shall be affixed to both sides and at the rear of the vehicle.”.

5.3.2.1.1 Delete „reflectorized”.

5.3.2.1.5 Amend to read as follows:

„5.3.2.1.5 If the orange-coloured plates prescribed in 5.3.2.1.2 and 5.3.2.1.4 affixed to the containers, tank-containers, MEGCs or portable tanks are not clearly visible from outside the carrying vehicle, the same plates shall also be affixed to both sides of the vehicle.”.

5.3.2.1.6 Replace „5.3.2.1.2 and 5.3.2.1.4” with „5.3.2.1.2, 5.3.2.1.4 and 5.3.2.1.5”.

5.3.2.1.7 Amend to read as follows:

„5.3.2.1.7 The requirements of 5.3.2.1.1 to 5.3.2.1.5 are also applicable to empty fixed or demountable tanks, battery-vehicles, tank-containers, portable tanks and MEGCs, uncleaned, not degassed or not decontaminated as well as to empty vehicles and containers for carriage in bulk, uncleaned or not decontaminated.”.

5.3.2.1.8 Amend the first sentence to read as follows:

„Orange-coloured marking which does not relate to dangerous goods carried, or residues thereof, shall be removed or covered.”.

5.3.2.2.1 In the first sentence, replace „The reflectorized orange-coloured plates” with „The orange-coloured plates shall be reflectorized and”.

Insert the following new text after „black border 15 mm wide.”: „The material used shall be weather-resistant and ensure durable marking. The plate shall not become detached from its mount in the event of a 15 minutes’ engulfment in fire.”.

Insert the following new paragraph, at the end, before the NOTE:

„For containers carrying dangerous solid substances in bulk and for tank-containers, MEGCs and portable tanks, the plates prescribed in 5.3.2.1.2, 5.3.2.1.4 and 5.3.2.1.5 may be replaced by a self-adhesive sheet, by paint or by any other equivalent process.

This alternative marking shall conform to the specifications set in this sub-section except for the provisions concerning resistance to fire mentioned in 5.3.2.2.1 and 5.3.2.2.2.”.

Remainder of the text unchanged.

5.4.1.1.1 In the paragraph (b), insert „in brackets” after „technical name”.

In the paragraph (c):

2nd indent: Add a Note to read as follows:

„NOTE: For radioactive material with a subsidiary risk, see also special provision 172.”.

3rd indent: Add, at the end of the first sentence, „or applicable according to a special provision referred to in Column (6)”.

In the paragraph (e), add the words „when applicable” after „the packages”, insert at the end: „UN packaging codes may only be used to supplement the description of the kind of package (e.g. one box (4G)).”.

In the paragraph (f), delete the words „with the exception of empty means of containment, uncleaned,”.

Amend paragraph (h) to read as follows:

„(h) the name and address of the consignee(s). With the agreement of the competent authorities of the countries concerned by the carriage, when dangerous goods are carried to be delivered to multiple consignees who cannot be identified at the start of the carriage, the words „Delivery Sale” may be given instead.”.

In the paragraph after (i) replace „(a), (b), (c) and (d) shall be shown... or in sequence (b), (c), (a), (d)” with „(a), (b), (c) and (d) shall be shown in the order listed above (i.e. (a), (b), (c), (d))”.

Replace the second example with:

„UN1098, ALLYL ALCOHOL, 6.1 (3), PG I”.

5.4.1.1.3 Replace the second example with:

„„WASTE, UN 1230 METHANOL, 3 (6.1), PG II””.

Replace the fourth example with:

„„WASTE, UN 1993 FLAMMABLE LIQUID, N.O.S. (toluene and ethyl alcohol), 3, PG II””.

5.4.1.1.6 Amend as follows:

„5.4.1.1.6 Special provisions for empty means of containment, uncleaned

5.4.1.1.6.1 For empty means of containment, uncleaned, which contain the residue of dangerous goods of classes other than Class 7, the words „EMPTY, UNCLEANED” or „RESIDUE, LAST CONTAINED” shall be indicated before or after the proper shipping name required in 5.4.1.1.1 (b). Moreover, 5.4.1.1.1 (f) does not apply.

5.4.1.1.6.2 The special provision of 5.4.1.1.6.1 may be replaced with the provisions of 5.4.1.1.6.2.1, 5.4.1.1.6.2.2 or 5.4.1.1.6.2.3, as appropriate.

5.4.1.1.6.2.1 For empty packagings, uncleaned, which contain the residue of dangerous goods of classes other than Class 7, including empty uncleaned receptacles for gases with a capacity of not more than 1000 litres, the particulars according to 5.4.1.1.1 (a), (b), (c), (d), (e) and (f) are replaced with „EMPTY PACKAGING”, „EMPTY RECEPTACLE”, „EMPTY IBC” or „EMPTY LARGE PACKAGING”, as appropriate, followed by the information of the goods last loaded, as described in 5.4.1.1.1 (c).

See example as follows: „EMPTY PACKAGING, 6.1(3)”.

In addition, in such a case, if the dangerous goods last loaded are goods of Class 2, the information prescribed in 5.4.1.1.1 (c) may be replaced by the number of the class „2”.

5.4.1.1.6.2.2 For empty means of containment other than packagings, uncleaned, which contain the residue of dangerous goods of classes other than Class 7 and for empty uncleaned receptacles for gases with a capacity of more than 1000 litres, the particulars according to 5.4.1.1.1 (a) to (d) are preceded by „EMPTY TANK-VEHICLE”, „EMPTY DEMOUNTABLE TANK”, „EMPTY TANK-CONTAINER”, „EMPTY PORTABLE TANK”, „EMPTY BATTERY-VEHICLE”, „EMPTY MEGC”, „EMPTY VEHICLE”, „EMPTY CONTAINER” or „EMPTY RECEPTACLE”, as appropriate, followed by the words „LAST LOAD:”. Moreover, paragraph 5.4.1.1.1 (f) does not apply.

See examples as follows:

„EMPTY TANK-VEHICLE, LAST LOAD: UN 1098 ALLYL ALCOHOL, 6.1 (3), I” or

„EMPTY TANK-VEHICLE, LAST LOAD: UN 1098 ALLYL ALCOHOL, 6.1 (3), PG I”.

5.4.1.1.6.2.3 When empty means of containment, uncleaned, which contain the residue of dangerous goods of classes other than Class 7, are returned to the consignor, the transport documents prepared for the full-capacity carriage of these goods may also be used. In such cases, the indication of the quantity is to be eliminated (by effacing it, striking it out or any other means) and replaced by the words „EMPTY, UNCLEANED RETURN”.

5.4.1.1.6.3 Unchanged.”.

5.4.1.2.1 (c) In the English text, in the second sentence, insert „drafted” before „in an official language”.

5.4.1.2.1 (d) Replace „the approval certificate” with „a copy of the competent authority approval” and add the following new sentence at the end: „It shall be drafted in an official language of the forwarding country and also, if that language is not English, French or German, in English, French or German unless agreements, if any, concluded between the countries concerned in the transport operation provide otherwise;”.

5.4.1.2.3.3 Amend the last sentence to read as follows:

„A copy of the competent authority approval with the conditions of carriage shall be attached to the transport document. It shall be drafted in an official language of the forwarding country and also, if that language is not English, French or German, in English, French or German unless agreements, if any, concluded between the countries concerned in the transport operation provide otherwise.”.

5.4.1.2.5.1 (c) Insert „symbol” after „SI prefix”.

5.4.1.2.5.3 Insert the following new paragraph:

„5.4.1.2.5.3 In case of international carriage of packages requiring competent authority design or shipment approval, for which different approval types apply in the different countries concerned, the UN number and proper shipping name required in 5.4.1.1.1 shall be in accordance with the certificate of the country of origin of design.”.

Renumber existing 5.4.1.2.5.3 as 5.4.1.2.5.4.

5.4.4 In the multimodal dangerous goods form, the left margin of Note (*), replace „proper shipping name, hazard class, UN No.” with „UN No., proper shipping name, hazard class”.

6.1.2.5 Under 2., replace „wooden barrel” with „(Reserved)”.

6.1.2.7 In the table, replace the text in the row for „Wooden barrels” with „(Reserved)”.

6.1.3.1 (d) Delete the NOTE.

6.1.4.6 Amend to read:

„6.1.4.6 (Deleted)”.

6.1.4.8.8 Add a new NOTE at the end to read as follows:

„NOTE: ISO 16103:2005 - „Packaging - Transport packaging for dangerous goods - Recycled plastics material”, provides additional guidance on procedures to be followed in approving the use of recycled plastics material.”.

6.1.5.1.6 Replace current text with the following:

„6.1.5.1.6 (Reserved)

NOTE: For the conditions for assembling different inner packagings in an outer packaging and permissible variations in inner packagings, see 4.1.1.5.1.”.

6.1.5.2.4 Amend to read:

„6.1.5.2.4 (Reserved)”.

6.1.5.2.5 In the Note, delete „high or average molecular mass”.

6.1.5.2.6 Amend the text beginning with „For high molecular mass polyethylene drums...” and finishing with „...with standard liquids (see 6.1.6).” to read as follows:

„For polyethylene drums and jerricans in accordance with 6.1.4.8 and if necessary, polyethylene composite packagings in accordance with 6.1.4.19, chemical compatibility with filling liquids assimilated in accordance with 4.1.1.19 may be verified as follows with standard liquids (see 6.1.6).”.

In the second paragraph (from „The standard liquids are representative...” to „...this procedure is not required”), delete „high or medium molecular mass” and add the following new sentence at the end:

„Storage is not required either for test samples which are used for the stacking test in case of the standard liquids „wetting solution” and „acetic acid”.”.

In the last paragraph, delete „high density, high or medium mass”.

6.1.5.2.7 In the first sentence, delete „high or medium molecular mass”.

6.1.5.3.1 In the table, delete „wooden barrels” under „Packaging”.

6.1.6 Delete „high or medium molecular mass”.

6.1.6.1 (a) Replace „1 to 10% of a wetting agent” by „1% of alkyl benzene sulphonate, or an aqueous solution of 5% nonylphenol ethoxylate which has been preliminary stored for at least 14 days at a temperature of 40 °C before being used for the first time for the tests,”.

6.1.6.1 (f) After the second sentence, insert the following text:

„A design type test with water is not required if adequate chemical compatibility is proved with wetting solution or nitric acid.”.

6.2.1.3.3.5.4 Amend footnote 1 to read as follows:

„1 See for example CGA Publications S-1.2-2003 „Pressure Relief Device Standards - Part 2 - Cargo and Portable Tanks for Compressed Gases” and S-1.1-2003 „Pressure Relief Device Standards - Part 1 - Cylinders for Compressed Gases”.”.

6.2.1.6.1 Amend subparagraph (c) to read as follows:

„(c) Checking of the threads if there is evidence of corrosion or if the fittings are removed;”

Amend the end of Note 2 under subparagraph (d) to read as follows:

„... based on acoustic emission testing, ultrasonic examination or a combination of acoustic emission testing and ultrasonic examination.”.

6.2.1.7.2 (f) In the second sentence, delete „With the exception of pressure receptacles of UN No. 1965 hydrocarbon gas mixture, liquefied, n.o.s.,”.

Add the following new sentence at the end:

„This mark is not required for pressure receptacles for UN No. 1965 hydrocarbon gas mixture, liquefied, n.o.s.;”.

6.2.1.7.2 (i) Amend the first sentence to read as follows:

„The water capacity of the receptacle in litres followed by the letter „L”. In the case of pressure receptacles for liquefied gases the water capacity in litres shall be expressed to three significant figures rounded down to the last digit.”.

6.2.1.7.7 Amend to read as follows:

„With the agreement of the competent authority, the date of the most recent periodic inspection and the stamp of the expert may be engraved on a ring of an appropriate material affixed to the cylinder when the valve is installed and which is removable only by disconnecting the valve from the cylinder.”.

6.2.2 Amend the existing references to standards EN 1442:1998 and EN 13769:2003 as follows:

| Reference | Title of document | Applicable sub-sections and paragraphs | |

| for design and construction | |||

| EN 1442:1998/A2:2005 | Transportable refillable welded steel cylinders for liquefied petroleum gas (LPG) - Design and construction. | 6.2.1.1 and 6.2.1.5 | |

| EN 13769:2003/A1:2005 | Transportable gas cylinders - Cylinder bundles - Design, manufacture, identification and testing | 6.2.1.1, 6.2.1.5 and 6.2.1.7 | |

In the table, in Column „Reference”:

- Add „+A1:2006” after „EN 13322-1:2003”;

- Add „+A1:2005” after „EN 14427:2004”, „EN 1968:2002” and „EN 12863:2002”; and

- Replace „EN 849:1996/A2:2001” with „EN ISO 10297:2006”.

In the table, for EN 14427:2004, in Column „Title of document”, insert the following new NOTE 2:

„NOTE 2: In 5.2.9.2.1 and 5.2.9.3.1, both cylinders shall be subject to a burst test when they show damage equal to or worse than the rejection criteria.”

(the existing NOTE becomes NOTE 1).

In the table, under the heading „for materials”, insert the following new row at the end:

| Reference | Title of document | Applicable sub-sections and paragraphs | |

| for materials | |||

| EN ISO 11114-4:2005 (except method C in 5.3) | Transportable gas cylinders - Compatibility of cylinder and valve materials with gas contents - Part 4: Test methods for selecting metallic materials resistant to hydrogen embrittlement | 6.2.1.2 | |

6.2.3 In the first sentence, replace „table of 6.2.2” with „tables of 6.2.2 or 6.2.5”.

Add the following new paragraphs before the last sentence („The requirements of 6.2.1... shall be met:”):

„Where an appropriate standard is referenced in the tables of 6.2.2 or 6.2.5 the competent authority shall, within two years, withdraw recognition for the use of any technical code for the same purpose.

This does not remove the competent authority’s rights to recognise technical codes to reflect scientific and technical progress or where no standard exists or to deal with specific aspects not addressed in a standard.

The competent authority shall transmit to the secretariat of UNECE a list of the technical codes that it recognises. The list should include the following details: name and date of the code, purpose of the code and details of where it may be obtained. The secretariat shall make this information publicly available on its website.”

6.2.4 Renumber current paragraphs 6.2.4.3.1, 6.2.4.3.2 and 6.2.4.3.3 as 6.2.4.3.1.1, 6.2.4.3.1.2 and 6.2.4.3.1.3 respectively and insert a new 6.2.4.3.1 to read as follows:

„6.2.4.3.1 Small receptacles containing gas (gas cartridges)”

In current 6.2.4.3.1 (renumbered 6.2.4.3.1.1), replace „Each aerosol dispenser and small receptacle containing gas (gas cartridges)” with „Each receptacle”.

Add the following new paragraphs:

„6.2.4.3.2 Aerosol dispensers

Each filled aerosol dispenser shall be subjected to a test performed in a hot water bath or an approved water bath alternative.

6.2.4.3.2.1 Hot water bath test

6.2.4.3.2.1.1 The temperature of the water bath and the duration of the test shall be such that the internal pressure reaches that which would be reached at 55 °C (50 °C if the liquid phase does not exceed 95% of the capacity of the aerosol dispenser at 50 °C). If the contents are sensitive to heat or if the aerosol dispensers are made of plastics material which softens at this test temperature, the temperature of the bath shall be set at between 20 °C and 30 °C but, in addition, one aerosol dispenser in 2000 shall be tested at the higher temperature.

6.2.4.3.2.1.2 No leakage or permanent deformation of an aerosol dispenser may occur, except that a plastic aerosol dispenser may be deformed through softening provided that it does not leak.

6.2.4.3.2.2 Alternative methods

With the approval of the competent authority alternative methods which provide an equivalent level of safety may be used provided that the requirements of 6.2.4.3.2.2.1, 6.2.4.3.2.2.2 and 6.2.4.3.2.2.3 are met.

6.2.4.3.2.2.1 Quality system

Aerosol dispenser fillers and component manufacturers shall have a quality system. The quality system shall implement procedures to ensure that all aerosol dispensers that leak or that are deformed are rejected and not offered for carriage.

The quality system shall include:

(a) a description of the organizational structure and responsibilities;

(b) the relevant inspection and test, quality control, quality assurance, and process operation instructions that will be used;

(c) quality records, such as inspection reports, test data, calibration data and certificates;

(d) management reviews to ensure the effective operation of the quality system;

(e) a process for control of documents and their revision;

(f) a means for control of non-conforming aerosol dispensers;

(g) training programmes and qualification procedures for relevant personnel; and

(h) procedures to ensure that there is no damage to the final product.

An initial audit and periodic audits shall be conducted to the satisfaction of the competent authority. These audits shall ensure the approved system is and remains adequate and efficient. Any proposed changes to the approved system shall be notified to the competent authority in advance.

6.2.4.3.2.2.2 Pressure and leak testing of aerosol dispensers before filling

Every empty aerosol dispenser shall be subjected to a pressure equal to or in excess of the maximum expected in the filled aerosol dispensers at 55 °C (50 °C if the liquid phase does not exceed 95% of the capacity of the receptacle at 50 °C). This shall be at least two-thirds of the design pressure of the aerosol dispenser. If any aerosol dispenser shows evidence of leakage at a rate equal to or greater than 3.3 x 10-2 mbar.l.s-1 at the test pressure, distortion or other defect, it shall be rejected.

6.2.4.3.2.2.3 Testing of the aerosol dispensers after filling

Prior to filling the filler shall ensure that the crimping equipment is set appropriately and the specified propellant is used.

Each filled aerosol dispenser shall be weighed and leak tested. The leak detection equipment shall be sufficiently sensitive to detect at least a leak rate of 2.0 x 10-3 mbar.l.s-1 at 20 °C.

Any filled aerosol dispenser which shows evidence of leakage, deformation or excessive weight shall be rejected.”.

6.2.4.3.3 Add a new paragraph to read as follows:

„6.2.4.3.3 With the approval of the competent authority, aerosols and receptacles, small, containing pharmaceutical products and non flammable gases which are required to be sterile, but may be adversely affected by water bath testing, are not subject to 6.2.4.3.1 and 6.2.4.3.2 if:

(a) They are manufactured under the authority of a national health administration and, if required by the competent authority, follow the principles of Good Manufacturing Practice (GMP) established by the World Health Organization (WHO) * ; and

(b) An equivalent level of safety is achieved by the manufacturer’s use of alternative methods for leak detection and pressure resistance, such as helium detection and water bathing a statistical sample of at least 1 in 2000 from each production batch.”.

6.2.5.2.1 Insert the following new entry at the end of the table:

| ISO 11119-3:2002 | Gas cylinders of composite construction - Specification and test methods - Part 3: Fully wrapped fibre reinforced composite gas cylinders with non-load-sharing metallic or non-metallic liners |

6.2.5.2.3 In the table, under „For the cylinder shell:”, delete the reference to ISO 7866:1999.

6.2.5.2.4 Add a new paragraph to read as follows:

„6.2.5.2.4 The following standard applies for the design, construction and initial inspection and test of UN cryogenic receptacles, except that inspection requirements related to the conformity assessment system and approval shall be in accordance with 6.2.5.6:

| ISO 21029-1:2004 | Cryogenic vessels - Transportable vacuum insulated vessels of not more than 1000 l volume - Part 1: Design, fabrication, inspection and tests |

6.2.5.6.3.1 In (a), insert „of personnel” after „responsibilities” and delete ”, and power of the management”.

In (b), replace „systematic actions” with „procedures”.

Delete the commas before „and” in (c) and (d).

6.2.5.6.4.10 Amend to read as follows:

„6.2.5.6.4.10 Modifications to approved design types

The manufacturer shall either:

(a) inform the issuing competent authority of modifications to the approved design type, where such modifications do not constitute a new design, as specified in the pressure receptacle standard; or

(b) request a subsequent design type approval where such modifications constitute a new design according to the relevant pressure receptacle standard. This additional approval shall be given in the form of an amendment to the original design type approval certificate.”.

6.2.5.8.2 In (g) add the following new last sentence at the end of the existing text:

„In the case of pressure receptacles for UN 1001 acetylene, dissolved and UN 3374 acetylene, solvent free, at least one decimal shall be shown after the decimal point and two digits for pressure receptacles of less than 1 kg;”.

In (k) and (l): Insert ”, any coating,” after „during filling” and replace „two” with „three” in the first sentence. Insert the following two new last sentences at the end of the existing text:

„At least one decimal shall be shown after the decimal point. For pressure receptacles of less than 1 kg, the mass shall be expressed to two significant figures rounded down to the last digit;”.

Consequential amendment: The same changes apply to 6.2.1.7.2 (f), (j) and (k).

6.2.5.8.7 Add the following new paragraph:

„6.2.5.8.7 For acetylene cylinders, with the agreement of the competent authority, the date of the most recent periodic inspection and the stamp of the body performing the periodic inspection and test may be engraved on a ring held on the cylinder by the valve. The ring shall be configured so that it can only be removed by disconnecting the valve from the cylinder.”.

6.4.5.2 (b) Amend to read as follows:

„(b) more than a 20% increase in the maximum radiation level at any external surface of the package.”.

Consequential changes in 6.4.5.4.1(c)(ii), 6.4.5.4.2(c), 6.4.5.4.4(c)(ii), 6.4.5.4.5(b)(ii) and 6.4.7.14(b).

6.4.7.16 In the first sentence, replace „liquids” with „liquid radioactive material”.

6.4.8.3 In the first sentence, replace „6.4.8.4,” with „6.4.8.5 and in the absence of insolation,”.

6.4.8.4 The text of current 6.4.8.13 becomes new 6.4.8.4, with the following amendments:

In the first sentence, insert „under exclusive use” before „shall not exceed 85 °C” and replace „6.4.8.4” with „6.4.8.5”. Delete the second sentence: („The package shall... exceeds 50 °C.”).

6.4.8.4 to 6.4.8.12 Renumber as 6.4.8.5 to 6.4.8.13. Amend all cross-references accordingly (applies to 5.1.5.1.2 (e), 6.4.8.2, 6.4.8.6 (current 6.4.8.5), 6.4.9.1, 6.4.10.1, 6.4.10.2, 6.4.17.2, 6.4.17.3, 6.4.23.5, 6.4.23.12 (p), 6.4.23.14 (n) and (q) (renumbered 6.4.23.14 (o) and (s))).

6.4.11.2 (a) Amend the end of the sentence after the formula to read: „provided that the smallest external dimension of each package is not less than 10 cm and that either:”.

Amend (iii) and the following paragraph to read as follows:

„(iii) there are not more than 5 g of fissile material in any 10 litre volume of material.

Neither beryllium nor deuterium shall be present in quantities exceeding 1% of the applicable consignment mass limits provided in Table 6.4.11.2, except for deuterium in natural concentration in hydrogen.”.